Davie Street Enterprises (DSE), our fictional case study company, has taken a great leap toward the edge and is using the data collected from the edge to perform predictive maintenance and improve its unplanned downtime and line resilience.

Once the edge project was completed, DSE saw unplanned downtime reduced by 50%—far above what it had expected. Although the project was a success, it wasn’t without its challenges. There were many delays as the company figured out the data requirements.

DSE also had to upgrade many sensors to ensure that it could get the quality data required to get the correct results. In DSE’s digital transformation, this was a huge step forward in making it an artificial intelligence (AI) company.

This article will look into how the previous project and a whole new set of problems will transform DSE into an AI company. It will explore the lessons learned both technically and organizationally. It will also show how the lessons learned powered solving new problems using AI.

Growing pains

DSE is a traditional company structured hierarchically and divided into multiple business units and IT departments. Introducing new technologies can sometimes be challenging, especially something as daunting as artificial intelligence and machine learning (AI/ML).

During the implementation of the predictive maintenance project, DSE learned the hard way that implementing an AI solution required skills it didn’t have in house. Data

Science and Data Engineering were totally new to this hundred-year-old company.

It also realized that mining data from different business units could be a challenge. For the predictive maintenance project, it needed data from the asset management system owned by the Operations Technology (OT) team. It also needed data from HR about the work schedule for maintenance personnel.

Production scheduling data was critical in knowing what lines would be available at certain times to perform the maintenance. Getting approvals and access to this data that lived in disparate systems in different formats across the company wasn’t easy.

Monique Wallace, DSE CIO, recognized all of these challenges and set out to make some organizational changes. She set up a new AI/ML Governance Council that would oversee all new AI/ML projects. The team was made up of leaders from across different functional teams. The people on the team could change based on the project; however, the structure of the team—including the different stakeholders—had to be maintained.

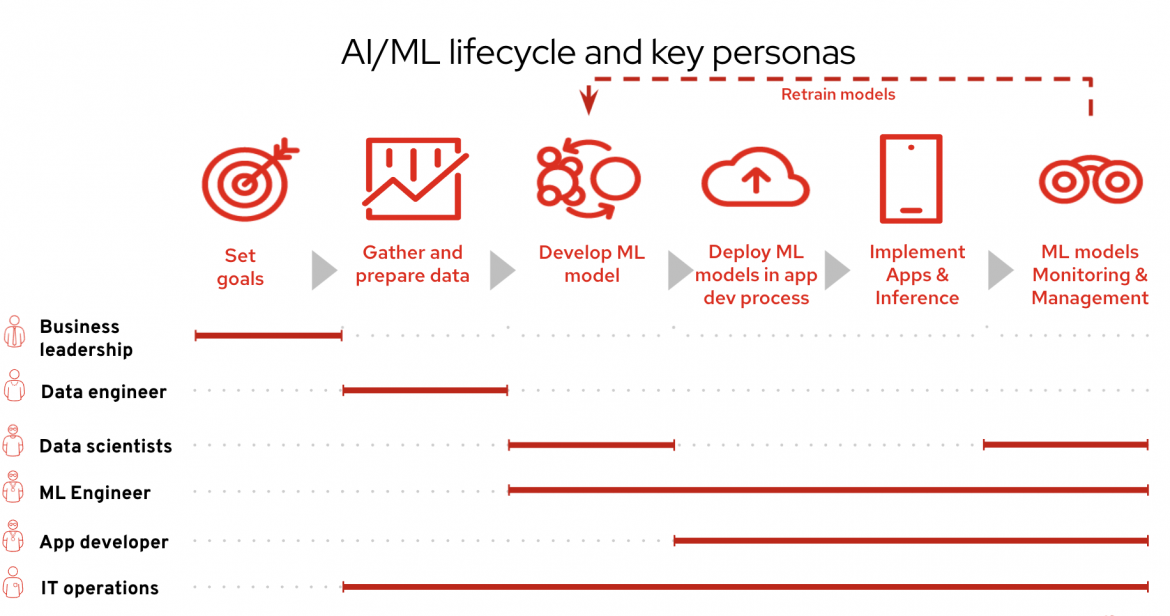

The team consisted of the following roles:

-

Business Leadership: Business analyst from the business unit that owns the project and has operational knowledge of the business requirements, needs and available data.

-

Senior Data Engineer: From IT and has a working knowledge of data storage and database technologies

-

Senior Data Scientist: From IT and has a working knowledge of AI/ML modeling

-

IT Operations Leader: From IT and has a working knowledge of software deployment practices and software system production scheduling

-

Principal Developer: Lead Developer from the business unit that owns the project and has operational knowledge of the affected applications

-

OT Operations Leader: From the OT organization and is engaged whenever there are operational technology data requirements

The new team quickly formed and defined its Machine Learning Operations (MLOPs) model that would govern the process of building, deploying, monitoring and maintaining models in production.

The model the team came up with can be seen in Figure 1.

Figure 1

Figure 1

New Challenges

A huge issue at DSE, and top of mind for many in the DSE leadership, is inventory management.

DSE has seen its warehouse space demands grow by 10% annually. This drives up operational costs and interferes with profitability. It is also having an impact on the plans for the new Smart Widgets. If Widget inventory demands continue to grow at this pace, this will cause significant storage capacity problems for the new Smart Widgets.

DSE transformed its old Part and Supplies (PAS) system into a modern platform that has connectivity to all suppliers. This connection is useful in gathering real-time data about supply chain scheduling and delays, and now that DSE has access to all this extra information, it wants to use it to optimize its supply chain and better manage and reduce inventory.

AI with SAS Viya and Red Hat OpenShift is the Answer

With the new AI/ML Governance Council in place and a strawman for model development and deployment, DSE is ready to take on this new corporate challenge of supply chain optimization.

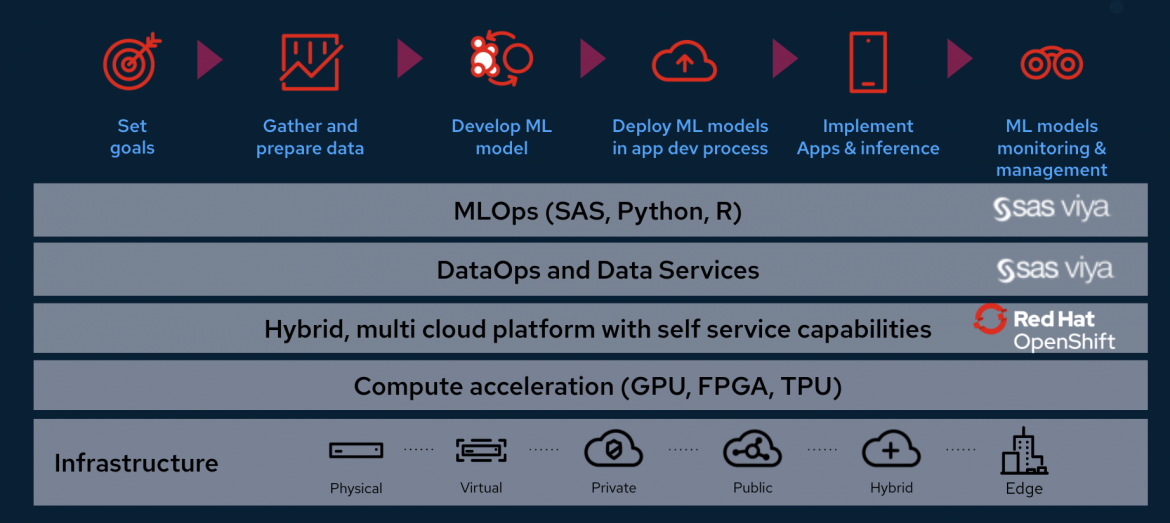

One of the key strategic decisions DSE has made on its digital transformation journey was to leverage Red Hat OpenShift as its hybrid cloud platform of choice. Red Hat OpenShift’s ability to support AI/ML platforms was one of the factors that helped DSE make that decision.

The last predictive maintenance project went very well and laid out a long-term strategy and platform that could support many other IT challenges, especially those requiring AI/ML as part of the solution.

The Council read about a SAS offering for supply chain optimization and thought Red Hat OpenShift and SAS Viya were a great combination in addressing the predictive maintenance problem. After having conversations with Red Hat and SAS consultants, the Council decided to start with this solution, since they have built up skills around it and were confident that the platform could support their MLOPs model and other solutions.

Figure 2 shows how Red Hat OpenShift and SAS Viya support the needs of the MLOPs model that was created by the Governance Council.

Figure 2

Figure 2

For this new supply chain optimization problem, DSE added SAS Viya Data Science as the tool of choice. SAS Viya data science offerings provide a comprehensive, scalable analytics environment that's quick and easy to deploy, enabling you to meet diverse business needs.

With the hybrid cloud platform and MLOps tooling in place, DSE embarks on following its MLOps process.

Goal Setting

The goals were very clear. DSE wants to reduce the growth in overhead expenditures caused by inventory overflow. It believes strongly that if it could reduce inventory by 15%, it could actually boost revenue by 2%. It’s a bold move but the council members are confident this goal is within reach.

Data Gathering

As part of the SAS Viya Data Science platform, there are tools such as SAS Data Preparation that will make finding and gathering the data much easier.

An AI/ML project is a continuum of mining for different data sources. Typically, the data sources change and evolve over the course of the project. The initial set of data sources to start with are supplier inventory data and scheduling, which can be gathered from the PAS system and production scheduling data that is stored in multiple on-prem data stores.

Develop / Deploy ML models

Another reason SAS Viya Data Science platform was chosen is that it also provides tools for low code or no code building of models. For a company new to AI, having a tool that makes building and deploying models easier is a big plus.

Implementing Apps

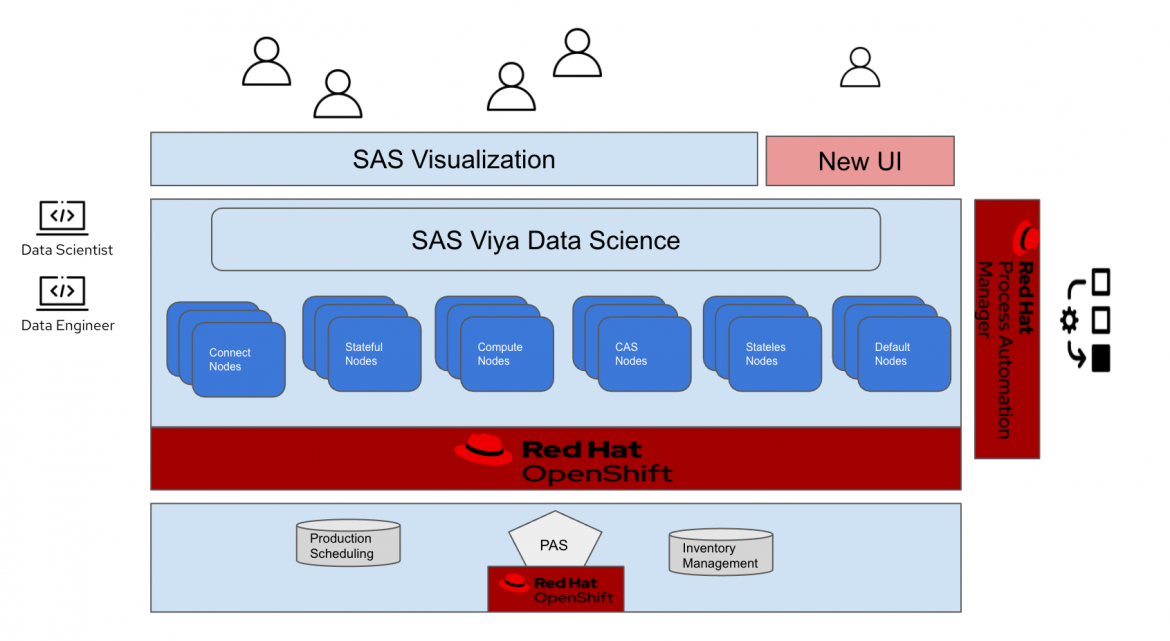

SAS Viya provides a sophisticated API that allows applications access to all the data and inference results. This will allow DSE to easily integrate the results into other applications and by using Red Hat Process Automation Manager into other corporate processes.

Model Monitoring / Management

SAS Model Manager (part of SAS Viya Data Science) automatically monitors model performance from inception to usage and retirement, regardless of the language used to create them. SAS Model Manager also provides performance benchmarking reports and can generate alerts to indicate model decay.

With the process and team in place, Daniel Mitchell, DSE Chief Architect, builds a high-level architecture so the technical teams have an understanding of what is being built. You can see his architecture in Figure 3.

Figure 3

Figure 3

Two down, many more to go!

DSE has embarked on a very challenging journey filled with tons of unknowns.

This article and the previous article took you on the journey of how a one-hundred-year-old company, consisting of many outdated tools and processes, can transform into an AI company.

Solving a critical problem allowed DSE to develop some skills in a lower-risk way. It also allowed the company to find suitable partners in Red Hat and SAS that provided the right infrastructure, tooling and consulting that could support not only the initial projects but the many AI/ML projects in the backlog.

Now that other business units can see the value of AI/ML and what it could do for their business unit and the company at large, lots of requests are coming in.

Über den Autor

John Senegal is an ecosystem solution architect who works with strategic global partners to build joint and ecosystem solutions. His technology focus is around the AI/Ml and edge/ IoT partner ecosystems.

Nach Thema durchsuchen

Automatisierung

Das Neueste zum Thema IT-Automatisierung für Technologien, Teams und Umgebungen

Künstliche Intelligenz

Erfahren Sie das Neueste von den Plattformen, die es Kunden ermöglichen, KI-Workloads beliebig auszuführen

Open Hybrid Cloud

Erfahren Sie, wie wir eine flexiblere Zukunft mit Hybrid Clouds schaffen.

Sicherheit

Erfahren Sie, wie wir Risiken in verschiedenen Umgebungen und Technologien reduzieren

Edge Computing

Erfahren Sie das Neueste von den Plattformen, die die Operations am Edge vereinfachen

Infrastruktur

Erfahren Sie das Neueste von der weltweit führenden Linux-Plattform für Unternehmen

Anwendungen

Entdecken Sie unsere Lösungen für komplexe Herausforderungen bei Anwendungen

Original Shows

Interessantes von den Experten, die die Technologien in Unternehmen mitgestalten

Produkte

- Red Hat Enterprise Linux

- Red Hat OpenShift

- Red Hat Ansible Automation Platform

- Cloud-Services

- Alle Produkte anzeigen

Tools

- Training & Zertifizierung

- Eigenes Konto

- Kundensupport

- Für Entwickler

- Partner finden

- Red Hat Ecosystem Catalog

- Mehrwert von Red Hat berechnen

- Dokumentation

Testen, kaufen und verkaufen

Kommunizieren

Über Red Hat

Als weltweit größter Anbieter von Open-Source-Software-Lösungen für Unternehmen stellen wir Linux-, Cloud-, Container- und Kubernetes-Technologien bereit. Wir bieten robuste Lösungen, die es Unternehmen erleichtern, plattform- und umgebungsübergreifend zu arbeiten – vom Rechenzentrum bis zum Netzwerkrand.

Wählen Sie eine Sprache

Red Hat legal and privacy links

- Über Red Hat

- Jobs bei Red Hat

- Veranstaltungen

- Standorte

- Red Hat kontaktieren

- Red Hat Blog

- Diversität, Gleichberechtigung und Inklusion

- Cool Stuff Store

- Red Hat Summit