Product timeliness refers to goods and products being in the right place at the right time, not out-of-date, and in line with customer expectations.

Perishable food items are perhaps the canonical example of products that have a limited shelf life. Even if they’re not labeled with a specific “sell by” or “use by” date, that wilted head of lettuce is not going to be a popular consumer choice. Furthermore, if you stock your produce department with fruits and vegetables that are routinely past their prime, many consumers will simply stop shopping at your store entirely.

But, many food products carry some sort of “use by” or “best by” labeling. Even though, with some exceptions like infant formula, these dates don’t mean the store can’t still sell the product anyway, though consumers will often pass on the old stock.

Outside of food and drugs, there are other product categories that also quickly lose value. Fast fashion, electronics, toys and many other product categories go out of style or are replaced with new models—meaning they can’t be sold at sticker price, if at all. Even boring seasonal products that don’t change much, like snow shovels, still tie up money that could be better used while they sit in a warehouse all summer.

Key performance indicators (KPIs) relevant to product timeliness include dead stock and inventory days on hand.

Business problem

Fundamentally, in the best case, unsold goods are “just” consuming working capital and shelf or warehouse space. A retailer may decide it’s a reasonable tradeoff to hold a seasonable product for the next selling season, although they may instead decide to hold an end of season sale or negotiate a transfer to a third-party. Whatever they decide to do, the result is lower profits than if they had been able to sell the product at the appropriate time.

In other cases, as we’ve seen, a store may need to offer deep discounts on an expiring item to have a chance at generating any revenue from it.. Everyone has seen “Manager’s Special” labels on meat and other items that are getting close to their “sell by” date. Consumers may even appreciate the discounting stores do to manage excess inventory. But, those watching over the finances at the company are probably less impressed.

In other cases, the product can't be sold at all for safety, liability, or reputational concerns, or because of rules set by regulators.

A key part of reducing inventory-related financial impact is identifying and managing stock that’s either about to expire or is otherwise becoming less relevant to your customer base.

Solution overview

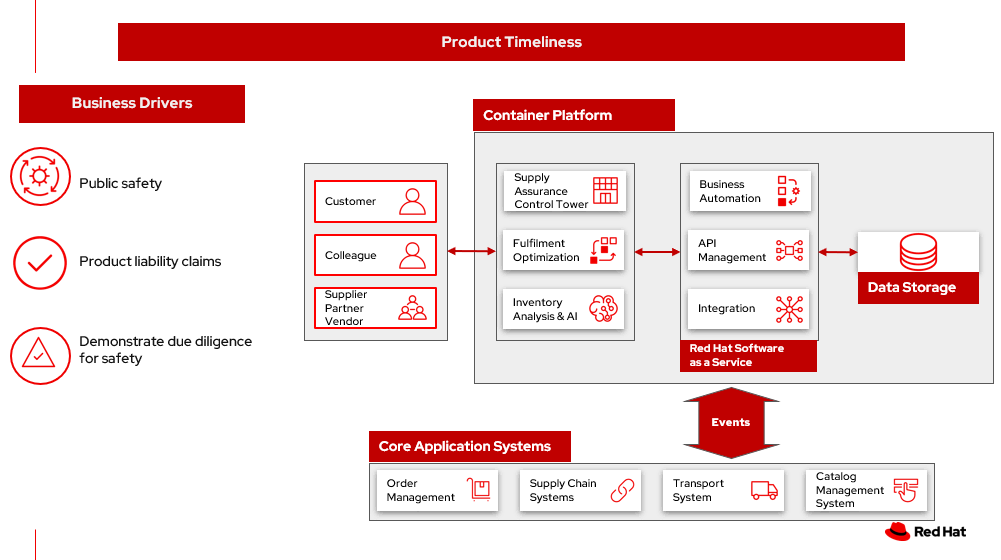

The product timeliness solution shown below uses components that can be grouped into three main categories as shown in the following diagram:

- Core application systems. These are often customer-provided technologies, such as order management and facilities management. These systems can include standalone applications, on-premises and cloud services, and databases.

- Foundational infrastructure. The Red Hat/IBM solution is built on Red Hat OpenShift with data routed through API management and events routed through business automation tools such as Business Automation Workshop.

- Inventory Optimization platform. This consists of a Supply Assurance Control Panel, Fulfillment Optimization, and Inventory Analysis and AI.

Architecture

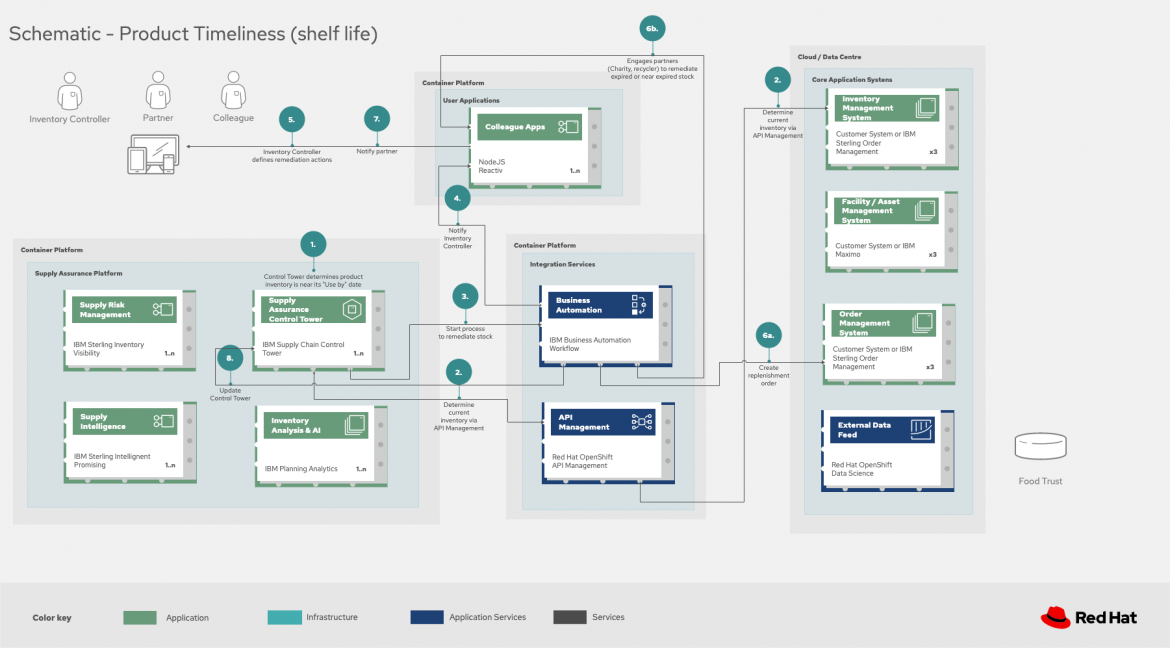

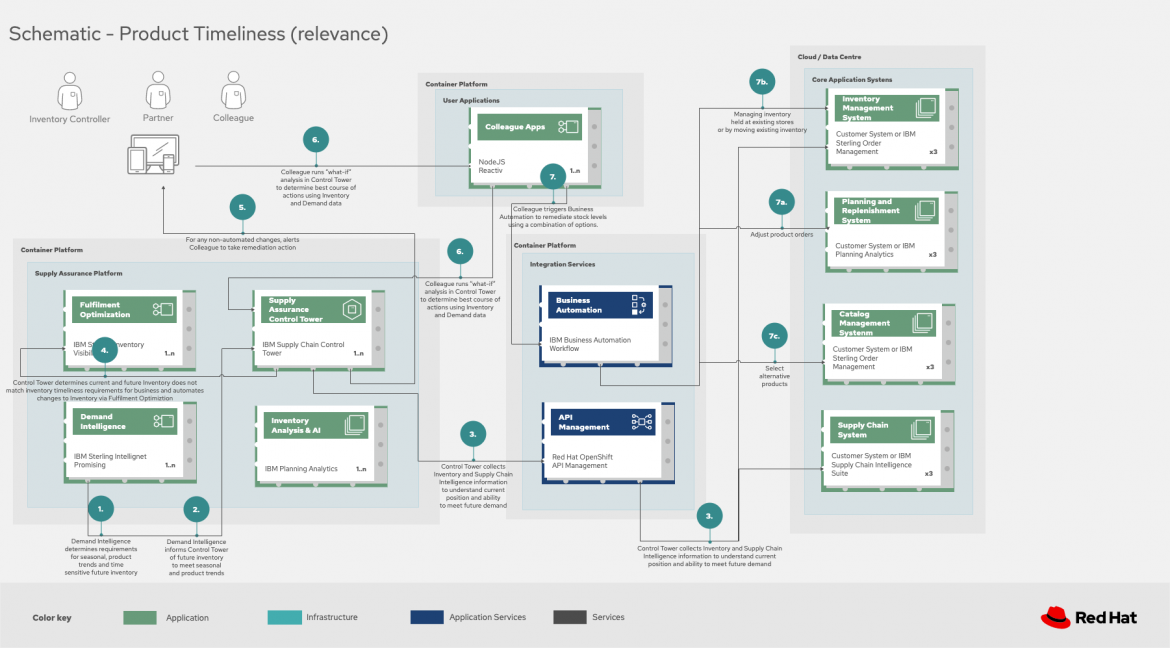

The following two charts illustrate the interaction of customer systems with supply chain optimization platform systems. They deal with shelf life and relevance respectively.

For the shelf life schematic, the relevant Inventory Control Tower heuristic is whether the product inventory is approaching an expiration or “use by” date. If so, it determines the current inventory via API Management and begins the process of remediating stock by notifying the Inventory Controller which defines the remediation action. Possible remediation actions include engaging partners, such as charities and recyclers, to remediate expired or near-expired stock and creating a replacement order. The Inventory Control tower is updated to close out the workflow.

Relevance requires a somewhat more complex workflow. In this case, Demand Intelligence determines the requirements for seasonal goods, products with particular types of demand trends, and time-sensitive future inventory. It then informs the Inventory Control Tower of needed future inventory to meet the demand of seasonal and product trends. It then collects Inventory (3a) and Supply Chain Intelligence (3b) information to understand the current position and ability to meet future demand. Next, Control Tower determines if current and future Inventory does not match inventory timeliness requirements for business, and automates changes to Inventory via Fulfillment Optimization.

For any non-automated changes, it then alerts someone to take remediation action. That person then runs a “what-if” analysis in the Inventory Control Tower to determine the best course of action using Inventory and Demand data. Finally, the person triggers Business Automation to remediate stock levels using a combination of options, including adjusting product orders, managing inventory held at existing stores or moving existing inventory, or selecting alternative products.

Action Guide

From a high-level perspective, there are several main steps your organization can take to drive innovation and move toward a digital supply chain. For specific steps on this approach, see The Action Guide details in the Own your transformation survey of 1500 CSCOs across 24 industries. It covers actionable steps in several areas of automation and sustainability, as well as the modernization to hybrid cloud platforms.

Summary

Part of inventory optimization is making sure that product timeliness is integrated into your inventory management processes. The result leads to the business being able to proactively demonstrate due diligence for safety, improve their customer experience and reduce financial loss due to products that have become less relevant. If product timeliness is not integrated, it leads to exposed risks to reputation, financial risk of regulatory fees, fines, liability claims, and in the worst case, eventual collapse of the business.

If you are interested in more solutions built with these and other products in Red Hat's portfolio, visit the Portfolio Architecture website and the Product Timeliness Portfolio Architecture, in particular.

Supply Chain blog series

This blog is part of a Supply Chain blog series:

- Supply chain optimization imperative - Read the blog

- Supply chain optimization - See the blog and associated Portfolio Architecture

- Demand risk – See the blog and associated Portfolio Architecture

- Loss and waste management – See the blog and associated Portfolio Architecture

- Product timeliness this blog and associated Portfolio Architecture

- Perfect order (coming soon)

- Intelligent order (coming soon)

- Sustainable supply (coming soon)

References

- McKinsey: How COVID-19 is reshaping supply chains

- Harvard Business Review: Three steps to prepare your supply chain for the next crisis

- Gartner: What is a Supply Chain Control Tower and what's needed to deploy one

- Gartner: Fulfillment Forecasting: The Key to Optimizing Retail Inventory Positioning

- Gartner: Supply Chain Risk Management (SCRM): What & Why Is It Important

- IBM Institute for Business Value: Own your transformation

- IBM Institute for Business Value: Balancing sustainability and profitability

- What is sustainability in business?

- Common practices and labels according to the USDA and FDA are explained in Expiring Products–Food & Ingredients by Michigan State University.

執筆者紹介

Mike is a 30+ year veteran in IT, having worked in various roles from data center management, operations, software development, software architect, and management. Most recently, Mike was General Manager for a small technology firm servicing the food service industry and led them through their infrastructure and application modernization efforts.

As a Chief Architect for Retail in the UK, Boyle engages in strategic dialog with IT decision makers and influencers across the ecosystem of Red Hat customers and partners. Boyle collaborates with architects and technologists across the globe to unlock the potential of open source solutions.

チャンネル別に見る

自動化

テクノロジー、チームおよび環境に関する IT 自動化の最新情報

AI (人工知能)

お客様が AI ワークロードをどこでも自由に実行することを可能にするプラットフォームについてのアップデート

オープン・ハイブリッドクラウド

ハイブリッドクラウドで柔軟に未来を築く方法をご確認ください。

セキュリティ

環境やテクノロジー全体に及ぶリスクを軽減する方法に関する最新情報

エッジコンピューティング

エッジでの運用を単純化するプラットフォームのアップデート

インフラストラクチャ

世界有数のエンタープライズ向け Linux プラットフォームの最新情報

アプリケーション

アプリケーションの最も困難な課題に対する Red Hat ソリューションの詳細

オリジナル番組

エンタープライズ向けテクノロジーのメーカーやリーダーによるストーリー

製品

ツール

試用、購入、販売

コミュニケーション

Red Hat について

エンタープライズ・オープンソース・ソリューションのプロバイダーとして世界をリードする Red Hat は、Linux、クラウド、コンテナ、Kubernetes などのテクノロジーを提供しています。Red Hat は強化されたソリューションを提供し、コアデータセンターからネットワークエッジまで、企業が複数のプラットフォームおよび環境間で容易に運用できるようにしています。

言語を選択してください

Red Hat legal and privacy links

- Red Hat について

- 採用情報

- イベント

- 各国のオフィス

- Red Hat へのお問い合わせ

- Red Hat ブログ

- ダイバーシティ、エクイティ、およびインクルージョン

- Cool Stuff Store

- Red Hat Summit